We provide technical design services and material selection for industrial products, static and mechanical calculations for construction work, and assembly details for installation.

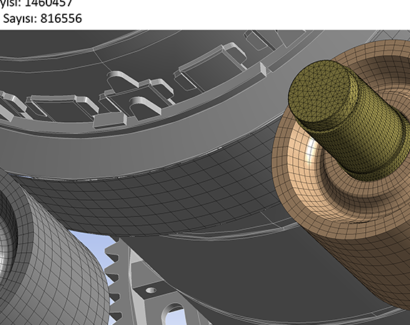

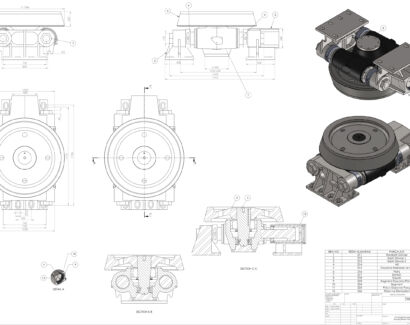

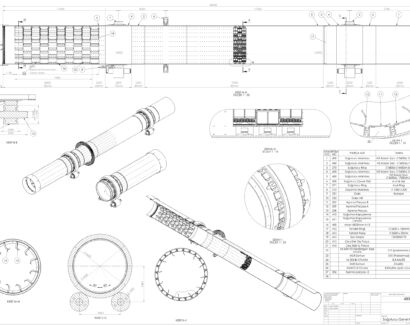

- 3D Design and Engineering Studies

- Technical Detail 2D and 3D Drawings, Weight and Dimension Determination

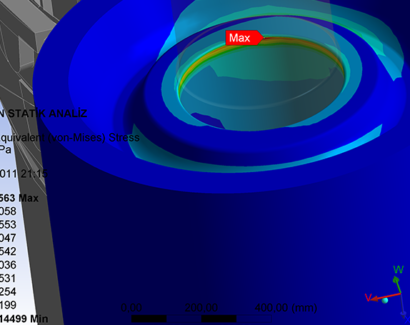

- Static Analysis

- Dynamic Analysis

- Assembly Operations

- BOM (Bill of Materials) List

In the cement, mining, and energy industries, we work around the clock with an international engineering team to provide the best engineering design to our customers.

We can summarize some of our work as follows:

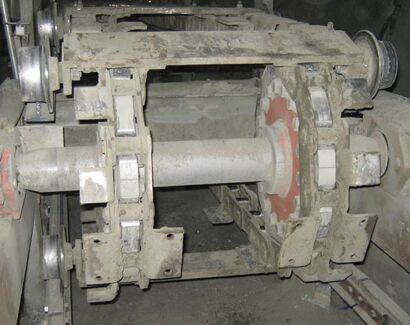

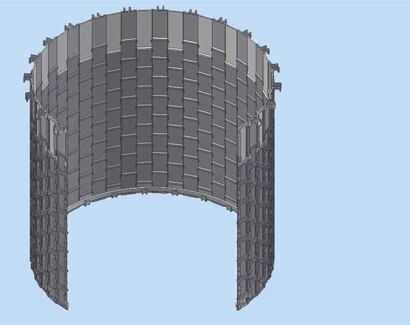

- Rotary Kiln Design and Manufacturing

- Kiln Girth Gear and Pinion Gear Design and Manufacturing

- Support Rollers and Bearings, Circumferential Ring Design and Manufacturing

- Rotary Dryer Design and Manufacturing

- Static and Dynamic Load and Stress Analysis

All engineering projects are carried out with professionals who are experts in their field, using the state-of-art computer programs.

UEK is dedicated to fulfilling the maintenance and service needs of businesses in the Cement, Mining, and Energy Industries, ensuring the most effective assistance with optimal team and equipment selection, all while considering the best possible timing and budget.

It is widely acknowledged that factories require prompt, systematic, and effective periodic maintenance and repairs. In light of this, UEK begins its pre-service research and planning, assembles an elite team, secures the necessary equipment, and delivers rapid and robust services.

UEK recognizes the potential losses in terms of time and money for companies when machine maintenance is delayed. Thus, UEK strives to secure the most productive outcomes in maintenance and service tasks for these businesses, with a focus on longevity and cost-efficiency.

Providing maintenance and service, UEK aims to render its services without halting the businesses’ production processes. To achieve this, it brings an elite technical and production crew together.